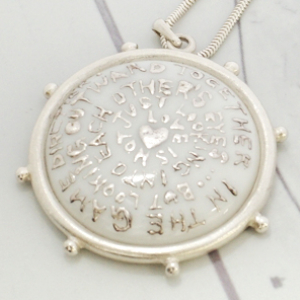

It is specifically formulated to bond to non-porous or glazed surfaces such as ceramic, porcelain, and glass. You can enjoy Silver Overlay drawing on those base materials. Its viscosity can be adjusted by water which increases the way of expression.

Silver ratio before firing: 90%

Purity after firing: Over 99.9%

Firing schedules: *See below for details.

Available package: 15g

Material form: Paste in plastic bottle

This is specifically formulated to bond to non-porous or glazed surfaces such as porcelain. Its viscosity can be adjusted by water which increases the way of expression. It turns into 99% silver form after firing. The surface of the fired area where Overlay Silver Paste was applied will be white and matte due to crystallization of silver, but a luster can be obtained by polishing. (Stainless blush, burnisher, sandpaper, file) Some silver settling may occur at bottom of jar. Stir the paste well with a brush or spatula before use. This product is water based and can dry up. Always keep the container tightly capped. If the paste dried up, add a little water to recover its original state. To dilute the paste, take out the necessary amount and place it in a different container. Then, add necessary amount of water. *Do not dilute it directly in the bottle.

You must fire the piece with a electric kiln, which is equipped with a temperature control.

Ramp the kiln to the applicable temperature depending on type of your project.

Ventilate your workroom well when firing.

| Steps | Process |

|---|---|

| ① | Place the piece in a cold or warm kiln (below 200℃/390°F). Ramp the kiln to the applicable temperature below. Take at least 15 minutes to reach the firing temperature. |

| ② | After reaching the selected temperature, turn off the kiln and cool down to 100℃/210°F. |

| Temperature | Holding time(at least) |

|---|---|

| 650℃/1202°F~800℃/1472°F | No needed |

| Steps | Process |

|---|---|

| ① | Place the piece in a cold or warm kiln (below 200℃/390°F). Ramp the kiln to the applicable temperature below. Take at least 15 minutes to reach the firing temperature. |

| ② | After reaching the selected temperature with appropriate holding time below, turn off the kiln and cool down to 100℃/210°F. Then, take out the piece. |

| Note | Be careful that quickly cooling the piece, such as quenching may cause it to break or crack. |

| Temperature | Holding time(at least) |

|---|---|

| 650℃/1202°F | 30 mins |

| 700℃/1292°F | 15 mins |

| 750℃/1382°F | 10 mins |

| 780℃/1436°F | 5 mins |

| 800℃/1472°F | No needed |