Art Clay Bronze(TM) is a clay material to make a wide range of pieces such as jewelry, craft designs, and objects like sculptures and models. Art Clay Bronze must be fired in an activated carbon under reducing atmosphere using a programmable electric kiln, with the resulting fired piece being solid alloy (Copper 90%, Tin 10%).

Copper/Tin alloy ratio in Clay state : 90 % (Rest of 10% is Binder and Water)

Shrinkage: Approx.10%-13% in length

Firing schedule: Please see the details below.

Available package:50g (2 pieces of 25g)

Material form: Lump in aluminum package

Art Clay Bronze is a clay material made from alloy powder, binder and water that you can use to make a wide range of pieces such as jewelry, craft designs, and objects like sculptures and models. Art Clay Bronze can be fired and its alloy powder fuses together in an electric kiln using carbon under reducing atmosphere, with the resulting fired piece being solid alloy (Copper 90%, Tin 10%). The percentage of alloy powder in Art Clay Bronze in the clay state is 90%.

Art Clay Bronze has been developed after testing many different metal formulas to ensure the best golden color.

Bronze is an alloy formed with mixture of copper and tin, therefore it gives

extremely high strength in both surface contact and bending pressure.

Bending strength* of fired Art Clay Bronze is approx. 3 times harder than Art

Clay Silver, and surface strength is approx. 2 times harder than Art Clay Silver

950.

*Bending strength is evaluated by force level in bending fired strip to 90

degrees. Higher force level means metal is harder to bend. This does not

necessarily mean that Art Clay Bronze has high viscosity or density for

reshaping.

Art Clay Bronze is a water-based clay, and dries naturally in the air. To avoid drying, when start molding your piece, only take out the needed amount to make your desired piece, and store well the rest of the clay using the instructions explained above. The shrinkage of Art Clay Bronze during firing is approximately 10%-13% in length, so please consider this when planning and making your piece.

Dry completely after molding. The dried clay will become hard like plaster, and you can easily enjoy the process of drilling, filing and sanding with hand tools and equipment. Follow the drying instructions and drying check method below.

Place the dried piece on a piece of stainless or glass plate while still warm. Leave for a couple of seconds, then remove your piece from the plate. If you do not see any vapor cloud on the plate where the piece was, drying is completed.

Drying guideline for drying a piece up to 1mm thick, 5g: *If the piece is larger than this size, drying will require more time.

| Way | Time/Temperature |

|---|---|

| Hot air dryer | More than 10 mins. *1 |

| Electric Hot Plate | More than 10 mins at 150°C/ 302°F |

| Electric Kiln | More than 10 mins at 150°C/ 302°F |

| Natural Air dry method | More than 24 hrs |

*1 : Place the piece as close as safely possible to the hot air while taking care not to drop the piece.

***DO NOT dry the piece over 250°C/482°F, or the binder will be destroyed during drying and deform the shape during the firing process.***

Art Clay Bronze needs to be fired...

1. PREPARATION

If you fire a ring, place a circle of firing blanket along the inside band of the ring. This will avoid marks caused by carbon when the clay shrinks during firing.

2. PREPARATION

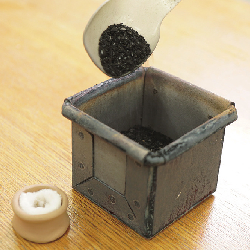

Spread more than 1 cm of activated carbon on the bottom of a firing pan.

3. PREPARATION

Place the piece on top of the carbon layer (if you fire multiple pieces together, always have at least 2cm carbon between pieces). Bury the pieces completely under 2cm carbon.

4. RAMP UP

Place the box farthest from the kiln door, and ramp up from room temperature to 820°C, taking at least 20 minutes to do so.

5. HOLD

Hold the kiln at 820°C for 2 hours.

6. COOL DOWN

Allow the bronze pieces to cool to room temperature before removing from the carbon.

7. Finishing

After firing, the piece appears matte brown. A beautiful bronze color is revealed after polishing.

As a character of alloy, oxide layer will be created on the surface. Have a surface polishing or use a solution made with pickling compound to remove oxide layer.

*After pickling, neutralize acid of the piece by dipping it in a baking soda mixed water (a small spoon of baking soda in a glass of water) for over 15 mins, then rinse well under running water.

*For use and proper disposal of the pickling solution, please be environmentally responsible and carefully follow the instructions of the pickling compound product.

After firing, the piece shows matte surface luster. Using metal wire brush, file, rotary tools, buff polishing will give beautiful metal luster. *When finished bronze exposed in the air, color will be changed as oxidation proceeds. The metal luster can be regained by polishing.

Q.)Can I use a 2-stage firing schedule for Art Clay Bronze??

A.)You can use Art Clay Bronze in 2-stage firing as an option especially if you prefer to burn off binders of a

thick piece, such as over 15mm thickness. Please note that it will give more strength, but also more shrinkage

after firing.

(Phase 1) Open shelf firing

Place dried pieces on a fiber board, and put them in a kiln. Fire from room temperature to 450°C, then

remove immediately. Let pieces cool down to room temperature. Spread at least 1 cm of activated carbon

on the bottom of a firing pan. Place pieces on the carbon layer, then cover with at least 2cm more carbon.

Place the pan into a kiln.

(Phase 2) Carbon firing

Ramp from room temperature to 820°C, holding 2 hours. Pieces must cool to room temperature in the

carbon.

Q.)How can I repair broken pieces after drying or firing?

A.)Add a small amount of water to Art Clay Bronze to make a thick paste to fill or mend the broken part. Make sure to use carbon firing after repairing.

Q.)Can I fire together with synthetic stones?

A.)Stones compatible with Art Clay Silver should be fine with the firing schedule of Art Clay Bronze. Test-firing stones is recommended. Compared to the open-shelf firing of Art Clay Copper, carbon firing Art Clay Bronze has a minimal chance of oxidation, therefore discoloration of synthetic stones with bronze rarely occurs.

Q.)Can I fire Art Clay Bronze together with silver findings (such as screw eye, bail back, or bezel)?

A.)You can fire several pieces at once as long as all pieces are buried completely in carbon. Allow 2cm carbon between pieces. Pieces touching within the carbon may result in underfiring.

Q.)Should I use a lid when firing Art Clay Bronze?

A.)Enough oxygen exists to burn off the binder even your piece is in carbon with a lid on the pan. It is recommended to have a lid on as it will contribute to a more beautiful finished color after firing.

Q.)Can I pickle fired Art Clay Bronze to remove oxidation? Does Art Clay Bronze discolor over time?

A.)Yes, you can pickle fired Art Clay Bronze to remove oxidation. Carbon firing will create only a very thin oxide layer on Art Clay Bronze, and you can brush/polish it off to remove it quite easily. Yes, Art Clay Bronze will discolor by oxidation as time goes by just like copper. Patina will be created on the surface exposed to high moisture or sweat. Polishing or pickling will remove oxidation or patina.

Q.)How does Art Clay Bronze compare with Art Clay Silver in terms of drying time, strength, or flexibility when dry?

A.)There is no big difference in drying time compared to any other Art Clay series. The strength and flexibility of Art Clay Bronze after drying is also almost the same as with other Art Clay series.

Q.)For those with metal allergies, is there any problem with wearing and/or working with the clay?

A.)In some rare cases, there may be a possibility of reaction due to the metal. If you have allergy to copper or tin, check with your Doctor if you can work with rubber gloves or should not work with it.

Q.)Is it possible to mix Art Clay Bronze with other Art Clay series?

A.)When combined with other ACS series products, the clay characteristics will change. Drying and firing conditions will also vary. Therefore, it is not recommended to mix clay types as there is possibility of damage during firing.

Q.)What is the best way to store leftover Art Clay Bronze?

A.)If Art Clay Bronze contacts in high humidity, oxidation will occur. Do not add moisture to any storage case. It is recommended that you keep Art Clay Bronze tightly wrapped with plastic wrap in an airtight container.

Q.)Can I put Art Clay Bronze in a syringe to use?

A.)Yes, you can use it as you would with regular Art Clay Silver. In that case, please use AIDA’s recommended empty syringe (Original item # : A-0031). Art Clay Bronze easily oxidizes in especially wet conditions. Make only as much syringe clay as you need, simply by adding water evenly to the bronze clay to a consistency good for syringe extruding.

Q.)What shrinkage should I consider for making rings with Art Clay Bronze?

A.)The metal portion of Art Clay Bronze is 90%

Copper and 10% Tin, and the organic portion is

binder and water. It shrinks a little more than the

regular Art Clay Silver series. For making rings,

please check the shrinkage guide shown.

Shrinkage after firing: Approx. 10-13%

*Note: Chart indicate Japanese sizing.