It is formulated for professional use. Silver 950 alloy metal clay gives approx. 60% stronger than basic type Art Clay Silver after firing. The strength gives more resistant to scratches, and more design options for delicate works. It has unique appearance with darker silver and heavier look. Purity after firing is Silver 950. Can be open fired in a kiln just like regular Art Clay Silver Series.

Silver alloy ratio before firing:90% (Rest of 10% is Binder and Water)

Silver purity after firing: 95%

Shrinkage:Approx.10-13%

Firing time: approx. 3 hours *See details below

Available package: 25g, 50g(2 pieces of 25g)

Material form: Lump in aluminum package

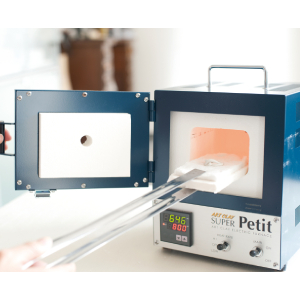

Fire in an electrical kiln with temperature control. Not suitable for gas stove or torch firing. Total firing time is approx. 3 hours.

| Steps | Firing way/time |

|---|---|

| ① | Place a piece at room temp. |

| ② | Ramp up until 500℃/932℉ and hold for 30mins. |

| ③ | Ramp up to 870℃/1598℉, and hold for 60 min. |

| ④ | Turn off the kiln and wait until the kiln drops to 200℃/392℉. |

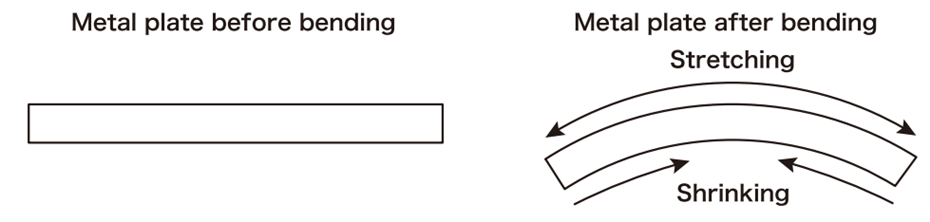

● Although ACS 950 has higher strength than fine silver Art Clay, it may break into pieces by extreme bending or reforming action. 2 different reactions taken place ni the outside and inside of metal when you bend it. Outside is extended and inside is shrunk. If outer surface cannot resist by extension, the piece will be broken apart.

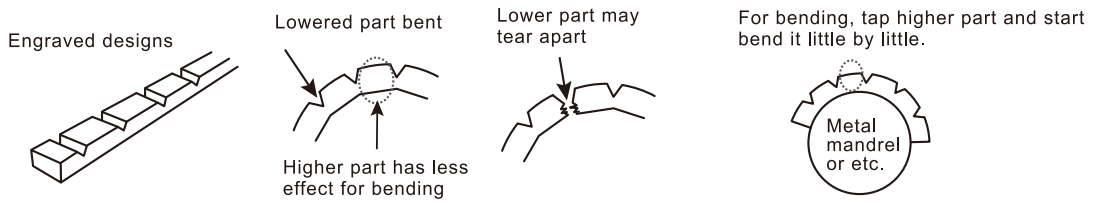

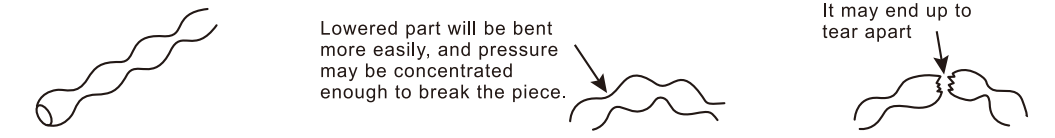

● Not only for fired Art Clay Silver, but also for many metals, designs explaind below are examples not suitable for bending process. In any case, sure to place the piece on a metal stand (such as metal mandrel, and metal anvil) when you bend or hammering. Work with piece consistently by processing it little by little.

Lowered part will be bent more easily. and pressure may be concentrated enough to break the piece.

if the piece does not have consistent thickness as clay forming design, it may tear apart. Also if the piece cannot be tapped to bend, it is not suitable for bending process.

Joined part, and repaired part are less strength than others, so it is not suitable for bending process.

Even alloy metal clay, it is soften when allealed after firing, so it needs to be harden. More bending process is continued, the metal wil be harder. it may break apart if you bend the piece once it was harden. If it is harden by hammering, and bending.

Put your fired piece in an electric kiln at

800 Deg.C for holding 1-2 minutes for making it soften.

*Annealing time depends on piece size.

You can take advantage of harder strength of ACS 950 to make Free size (Opened joint) ring design. However, it is not recommended to make ring designs such as the ones you change ring size by open and close action frequently, and/or extremely thin or small diameter ring. When you adjust ring size a bit, suggested to anneal it, then work on metal mandrel.

*From here, ACS stands for Art Clay Silver.

Q.) Does it feel different to work with compared to regular ACS?

A.) Working with ACS 950 is not significantly different from working with regular ACS. If the clay feels a little stiff when first taking out of the package, knead well before use.

Q.) Compared with the regular ACS, Is there a difference in drying time? Also do you have the strength and flexibility difference after drying?

A.) There is no difference in drying time. The strength and flexibility after drying are also almost the same as with regular ACS.

Q.) For those with metal allergies, is there any problem with wearing and/or working with the clay?

A.) In some rare cases, there may be a possibility of reaction due to the metal. In general, because of the high purity of the clay and when compared to SV925, which is generally used in jewelry, if there is no problem with regularly worn silver accessories, the possibility of reaction is low.

Q.) Can I make Paste from ACS 950 for fixing and joining dried pieces of ACS 950? Also, can I use my own paste of ACS 950 for fixing or joining fired ACS 950 pieces?

A.) You can make Paste of ACS 950 by mixing with water, and you can use it for fixing and joining dried ACS 950 pieces. For fixing and joining fired ACS 950 pieces, please use regular ACS Paste Type to re-fire it at 800 Deg.C (1472F).

Q.) Can I use regular ACS Paste type with ACS 950 works?

A.) Yes, you can use regular ACS paste type for dried pieces, and fired pieces of ACS 950.

Q.) Is it possible to mix ACS 950 with other ACS series? (Regular Art Clay Silver, Slow Tarnish)

A.) When combined with other ACS series products, the clay characteristics will change. Drying conditions and firing conditions will also vary, Therefore it is not recommended to mix clay types as there is possibility of damage during firing.

Q.) What is the shrinkage after firing ACS 950?

A.) Shrinkage is approx. 10 to 13% in length.* For making ring, allow extra shrinkage 1 size more than the one was made with regular ACS.

Q.) What is the purity after firing? Also, can the piece be hallmarked?

A.)Silver purity will be 95% after firing. You can hallmark your pieces [Sterling] [SILVER] [SV950] [SILVER950] . According to the definition of assay office in UK, silver purity of 92.5% over and less than 95.8% can be hallmarked as [Sterling].

Q.) Is it possible to fire ACS 950 with synthetic stones?

A.) Yes, the same stone specifications apply as with regular Art Clay Silver products.

Q.) Is it possible to solder ACS 950 work?

A.) Soldering is possible but care needs to be shown with soldering absorbed in metal due to porousness of the fired ACS 950.

A.) Soldering is possible but care needs to be shown with soldering absorbed in metal due to porousness of the fired ACS 950.

A.) Yes, and it is the same process as with regular Art Clay series products.

Q.) Can I store remainder of ACS950 in a moisturizing case?

A.) If ACS950 contacts in higher humidity in a moisturizing case, oxidation will proceed. It is recommended that you keep it tightly with plastic wrap in the moisturizing case.

Q.) Do I need to use acid to remove any oxidation?

A.) You can use acid on your choice, but it is not necessary. It turns grayish color right after firing as it has very small amount of copper in ACS 950, but it turns silver shine by polishing.

Q.) Can I put ACS 950 in a syringe to use?

A.) Yes, you can use it as you use with regular ACS. In that case, please use AIDA’s recommended empty syringe (Original item # : A-0031).